News

News

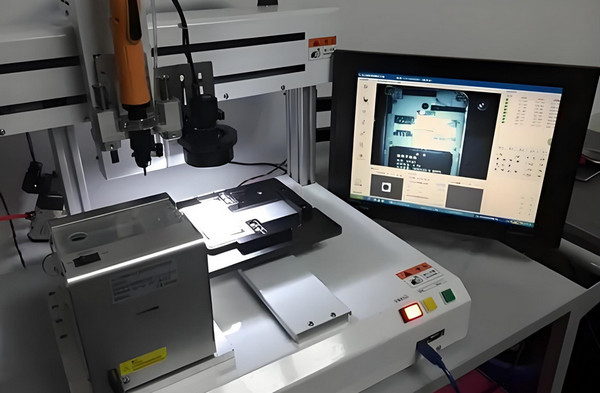

The advent of automation has revolutionized various industries, notably manufacturing. Among the significant advancements is the CCD vision automatic positioning screw locking machine, a crucial tool in precision assembly processes. This machine integrates CCD (Charge-Coupled Device) vision technology with robotic automation to enhance efficiency, accuracy, and productivity in screw fastening tasks.

CCD vision technology involves using a CCD sensor to capture high-resolution images. These sensors convert light into electronic signals, enabling the machine to analyze and process visual data with exceptional precision. The primary function of CCD vision in screw locking machines is to detect and identify the exact location and orientation of screws and components.

CCD Camera: The CCD camera captures real-time images of the workpiece. It ensures high accuracy in identifying the screw positions, even in complex assemblies.

Image Processing Software: Advanced algorithms process the captured images to determine the precise coordinates for screw placement. The software can recognize different screw types and their respective locations.

Robotic Arm: The robotic arm, guided by the processed image data, accurately positions the screwdriver. It moves with high precision, ensuring each screw is placed correctly without damaging the components.

Screw Feeder: The screw feeder automatically supplies screws to the screwdriver, reducing manual intervention and increasing operational efficiency.

Control System: The control system coordinates all components, ensuring seamless operation. It integrates with existing manufacturing systems for comprehensive process control.

Precision and Accuracy: The CCD vision system provides unmatched accuracy in locating screws and components, reducing errors and rework.

Enhanced Efficiency: Automation significantly increases the speed of screw fastening, leading to higher throughput and productivity.

Consistency: The machine ensures uniformity in screw fastening, maintaining consistent torque and depth across all screws.

Cost Savings: Reduced manual labor and minimized errors translate into significant cost savings over time.

Versatility: These machines can handle various screw types and sizes, making them suitable for diverse manufacturing applications.

CCD vision automatic positioning screw locking machines are extensively used in industries requiring high precision and efficiency. Key sectors include:

Electronics: Assembling small electronic components where precision is critical.

Automotive: Ensuring the reliability and safety of assembled parts.

Aerospace: Meeting stringent quality standards in component assembly.

Medical Devices: Assembling intricate medical devices with high accuracy requirements.

The continuous evolution of CCD vision technology and automation will lead to further advancements in screw locking machines. Future trends include:

AI Integration: Incorporating artificial intelligence to enhance image processing and decision-making capabilities.

IoT Connectivity: Enabling real-time monitoring and control through Internet of Things (IoT) integration.

Enhanced Flexibility: Developing machines capable of handling even more complex assemblies and varied screw types.

The CCD vision automatic positioning screw locking machine represents a significant leap in manufacturing automation. Its ability to enhance precision, efficiency, and consistency makes it an invaluable tool in modern assembly lines. As technology continues to evolve, these machines will undoubtedly become more advanced, further driving innovation and productivity in various industries.

Copyright © Shenzhen City Huya Technology Co., Ltd. All Rights Reserved Sitemap | Powered by XiaoLiang