News

News

Automatic screw tightening machines, also known as automatic screw locking machines, are essential tools in modern manufacturing processes. These machines streamline the assembly line, ensuring precision and efficiency. They come in various forms, each tailored to specific needs and applications. In this article, we will delve into the key types and features of automatic screw tightening machines, providing a detailed understanding of their operation and benefits.

Multi-axis screw machines are designed to handle complex assembly tasks requiring precision and speed. They can operate on multiple axes simultaneously, making them ideal for high-volume production lines. These machines ensure consistent torque and alignment, reducing the risk of errors and improving overall product quality.

Desktop screw machines are compact and versatile, suitable for small to medium-sized production runs. They are easy to integrate into existing workspaces and offer a high degree of flexibility. These machines are perfect for applications where space is limited but precision is crucial.

Handheld screw machines are designed for manual operation, providing the operator with control over the screw tightening process. These machines are portable and can be used in various settings, making them ideal for maintenance and repair tasks. They combine the precision of automatic machines with the adaptability of manual tools.

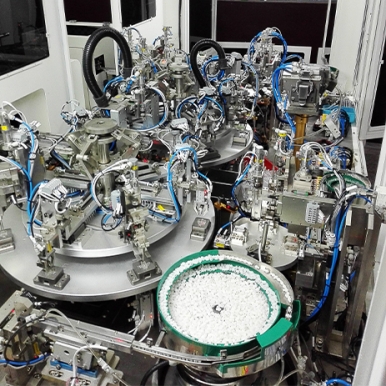

Rotary screw machines utilize a rotating table to position and secure parts for screw tightening. This design allows for continuous operation and high throughput, making them suitable for mass production environments. The rotary mechanism ensures that each component is accurately aligned and tightened, enhancing overall efficiency.

XYZ axis screw machines offer three-dimensional movement, allowing for precise placement and tightening of screws in complex assemblies. These machines are highly programmable and can be customized to meet specific production requirements. Their versatility makes them a valuable asset in industries ranging from electronics to automotive manufacturing.

Pneumatic screw machines use compressed air to drive screws into place. These machines are known for their speed and reliability, making them suitable for high-volume production lines. They offer consistent performance and are relatively low maintenance, providing an efficient solution for various assembly tasks.

Custom screw machines are tailored to meet unique production needs. These machines can be designed to accommodate specific screw types, sizes, and assembly requirements. Customization ensures that the machine integrates seamlessly into the production line, enhancing productivity and reducing downtime.

One of the primary advantages of automatic screw tightening machines is their ability to deliver precise and consistent results. These machines are equipped with advanced control systems that ensure each screw is tightened to the exact specifications, reducing the risk of over-tightening or under-tightening.

Automatic screw machines significantly increase production efficiency by automating the screw tightening process. This automation reduces the time required for each assembly task, allowing for higher output and shorter production cycles.

Many automatic screw machines are highly flexible and can be programmed to handle various screw types and sizes. Customization options allow manufacturers to tailor the machines to their specific needs, ensuring optimal performance and integration into existing workflows.

By automating the screw tightening process, these machines reduce the need for manual labor, lowering labor costs and minimizing the risk of human error. This automation leads to more efficient use of resources and higher overall productivity.

Automatic screw machines enhance workplace safety by minimizing the need for manual handling of screws and tools. This reduction in manual intervention decreases the risk of injuries, contributing to a safer working environment.

Automatic screw tightening machines are indispensable in modern manufacturing, offering precision, efficiency, and flexibility. Whether it's a multi-axis, desktop, handheld, rotary, XYZ axis, pneumatic, or custom machine, each type brings unique advantages to the production line. By understanding the features and benefits of these machines, manufacturers can make informed decisions to enhance their assembly processes and improve overall productivity.

Bull row insertion button switch assembly machine

This article details the male socket push-button s......

Bull row insertion button switch assembly machine

This article details the male socket push-button s......

Copyright © Shenzhen City Huya Technology Co., Ltd. All Rights Reserved Sitemap | Powered by XiaoLiang