The Huya visual inspection equipment adopts a high-efficiency visual inspection system. Through the vibration plate or the elevator for feeding, the materials are neatly arranged on the detection glass plate surface. The industrial CCD cameras distributed around the glass plate capture the images of the materials to be detected, and the visual inspection system analyzes and detects them, and the detection results are classified and processed to the corresponding exits. Thus, intelligent, high-efficiency, and low-cost automated inspection operations are realized.

The equipment is independently developed automatically, with a high degree of automation and wide application.

Automatic feeding and discharging mechanism and material shortage alarm system (the vibration plate or elevator can be configured as required).

High-efficiency visual inspection system, with a wide detection range, high detection accuracy, and simple operation.

High-resolution cameras from German CCD are selected, with reliable quality and relatively good performance.

The detection results can be customized, and the equipment automatically classifies and processes "qualified" and "unqualified".

Classify and store a large number of product files and data.

Remote networking upgrade and related system maintenance are available.

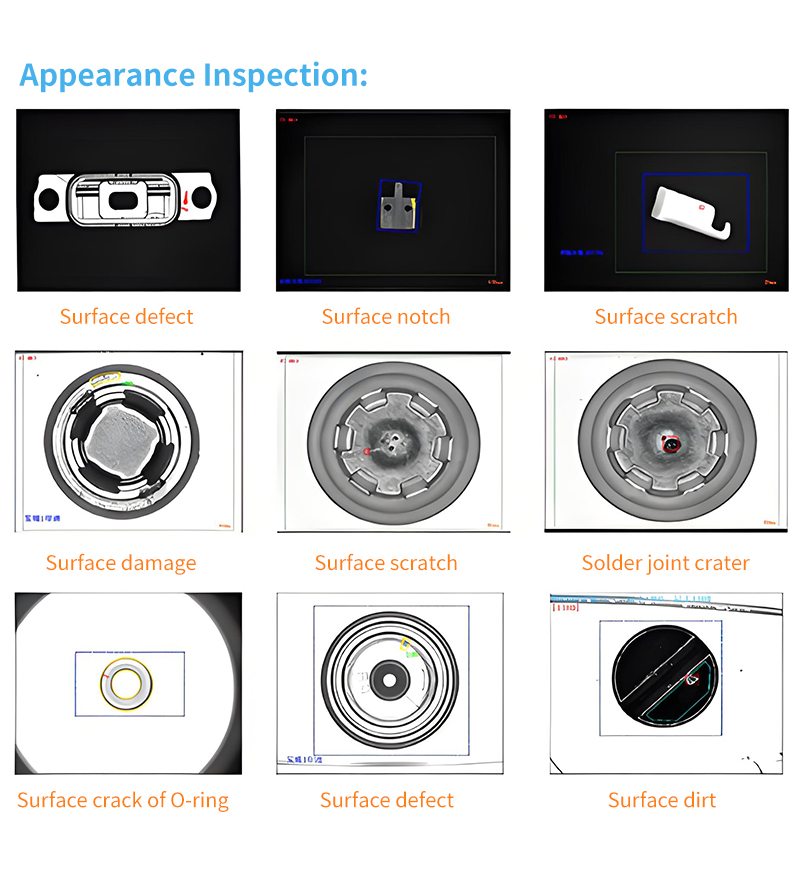

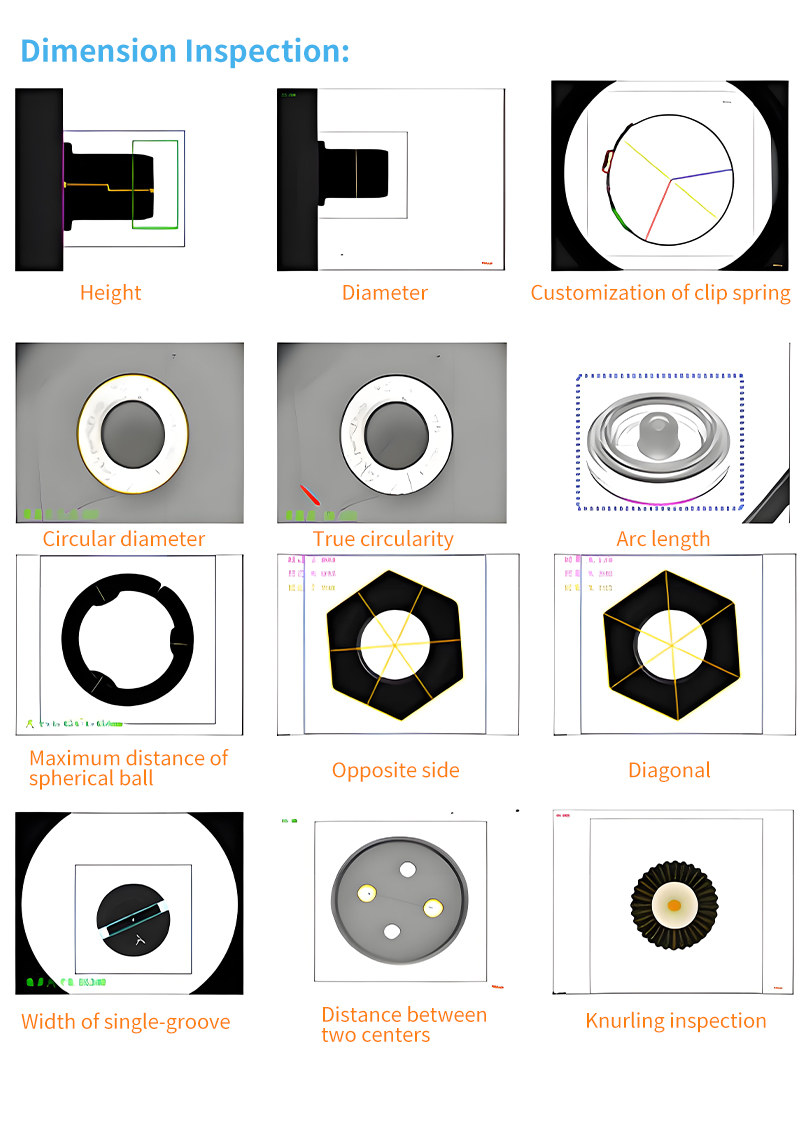

O-ring detection: Dimension detection: outer diameter, inner diameter, wire diameter, height; Surface defect detection: appearance defects such as burrs, lack of materials, fractures, adhered materials, bubbles, flow marks, deformations, mixed materials, etc., as well as appearance defects on the inner and outer sides.

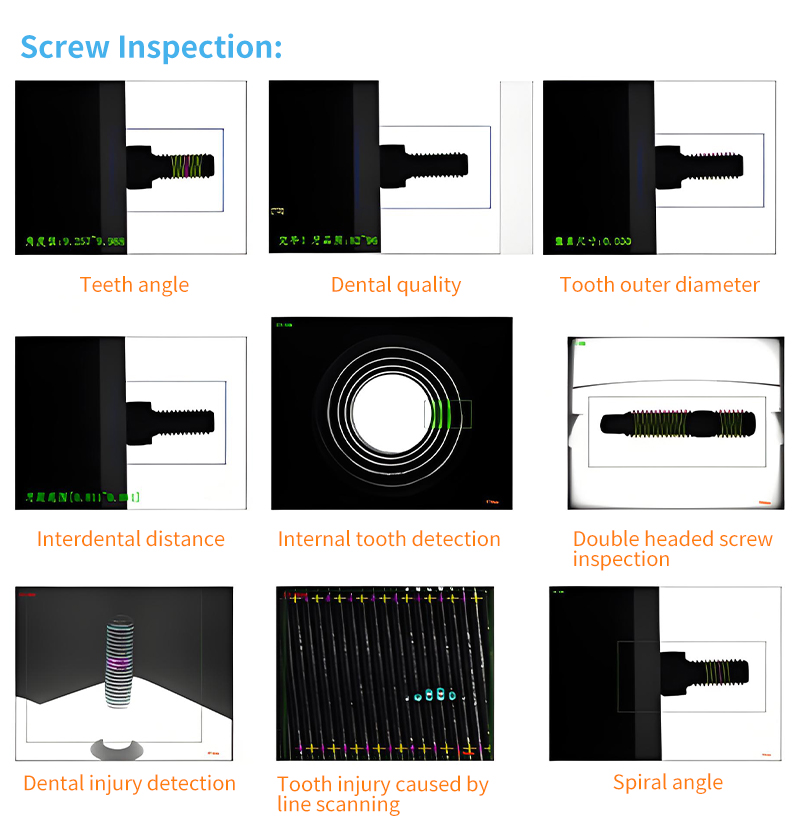

Screw detection: Multiple segment heights, multiple widths, broken needles, plugged holes, ineffective thread length (thread height under the neck), root diameter of the thread, outer diameter of the thread, thread pitch, inclined thread, poor thread rolling, screw length, whether there is electroplating on the head, whether there is a chamfer, plugged holes, eccentricity, whether there is a thread, etc.

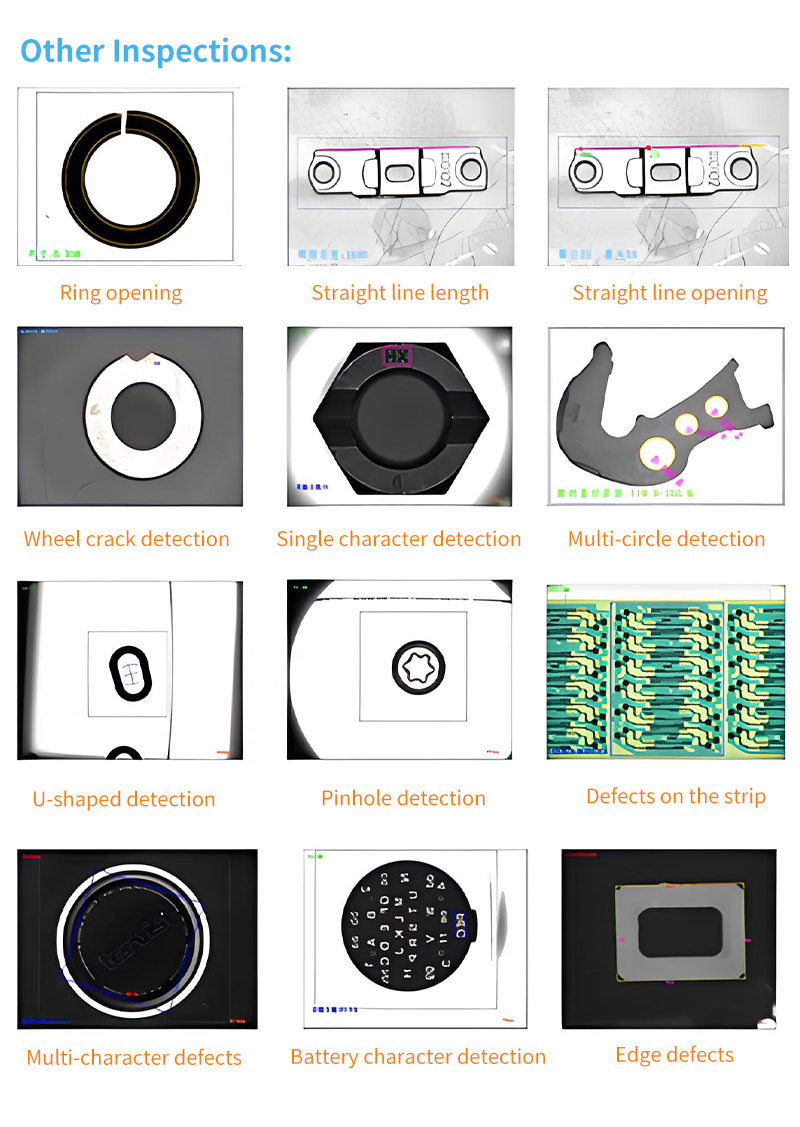

Other detections: Various dimension detections, surface defect detections, surface features, mark detections, character detections, barcode recognition, irregular defect detections, mechanical positioning, assembly detections, customized detections, etc.

Application scope: Applicable to the detection of various products such as O-type rubber rings, oil seals, screws, nuts, gears, precision hardware parts, plastic parts, electronic parts, etc.

Copyright © Shenzhen City Huya Technology Co., Ltd. All Rights Reserved Sitemap | Powered by XiaoLiang