A visually inspection machine tailored for hardware components features high-transparency glass for dual-side inspection, with a flexible setup accommodating 1 to 8 CCD camera kits. It boasts an inspection speed ranging from 300 to 1200 pieces per minute. Supporting both vibratory bowl feeders and elevators for automated feeding, it includes an automatic alarm system for material depletion. Comprehensive inspections cover dimensions and various defects, enhancing quality control processes through remote upgrade capabilities. Measuring 1000mm x 1000mm x 1900mm, it is designed to fit seamlessly into standard industrial settings.

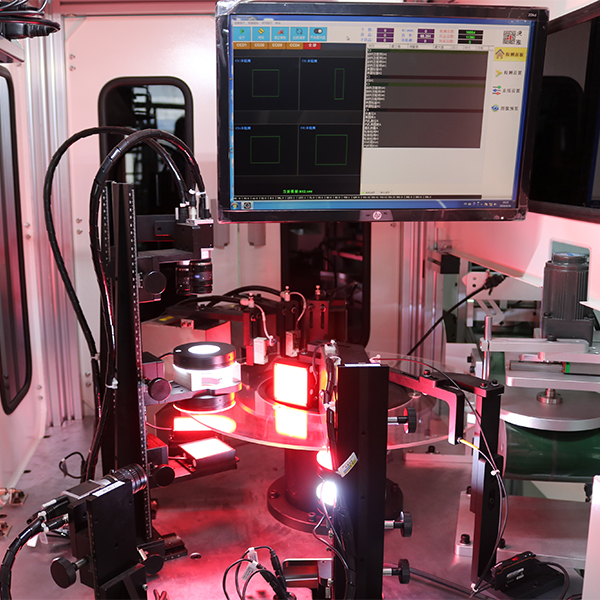

Equipped with high-transparency optical glass, allowing test pieces to be placed stably for simultaneous inspection of both upper and lower surfaces.

Optional configuration of a vibrating feeder or elevator for automatic feeding, with output capable of connecting to packaging machines, and automatic alarm for material shortage.

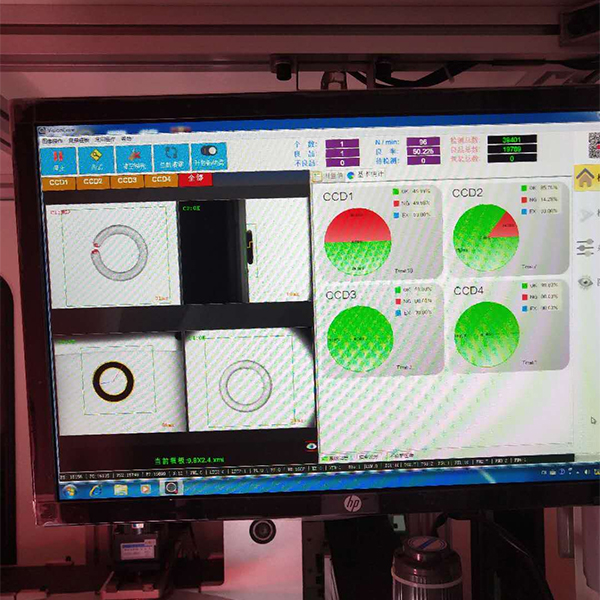

Single glass plate design, with the flexibility to accommodate 1-8 sets of high-resolution CCD cameras as required.

Inspection speed ranges from 300 to 1200 pieces per minute, depending on the material being inspected.

Inspection scope encompasses screws, nuts, turned & milled parts, stamped parts, metallurgical components, among other hardware products.

Customizable inspection results including "Pass," "Fail," and "Re-test."

Supports storage of a large volume of product profiles and data.

Enables remote network upgrades and system maintenance.

Dimensional inspection, surface defect detection, appearance defects, shape inspection, thread pitch and angle measurement, thread damage detection, etc.

Dimensions: 1000mm x 1000mm x 1900mm

Weight: 550KG

Power Supply: 220V, 50Hz, 5KW

Pneumatic Source: Filtered and dried air at 0.6MPa

Copyright © Shenzhen City Huya Technology Co., Ltd. All Rights Reserved Sitemap | Powered by XiaoLiang