News

News

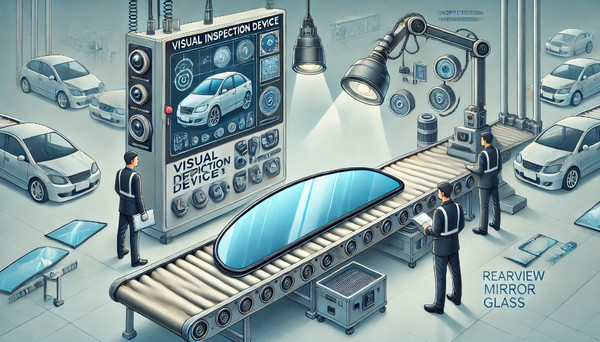

Quality inspection of rearview mirror glass is a crucial part of the automotive manufacturing process. With technological advancements and changing market demands, companies face two primary options for inspection: visual inspection equipment and outsourced inspection services. This article will detail the pros and cons of these two methods and provide specific guidelines to help companies make the best decision in different scenarios.

Pros:

High Precision: Visual inspection equipment uses high-resolution cameras and advanced image processing algorithms to accurately detect quality issues in rearview mirror glass, such as surface scratches, bubbles, and stains.

High Automation: The equipment can operate 24/7 continuously, reducing human error and increasing production efficiency.

Real-time Feedback: The equipment provides immediate inspection results, facilitating timely adjustments in the production process and reducing defect rates.

Long-term Cost Efficiency: Although the initial investment is high, the long-term use of the equipment results in lower costs.

Cons:

High Initial Investment: Purchasing and installing visual inspection equipment requires a significant initial investment.

Maintenance Costs: The equipment requires regular maintenance and software upgrades, leading to higher maintenance costs.

Technical Dependence: Professional technical personnel are needed to operate and maintain the equipment, increasing human resource costs.

Pros:

High Flexibility: Companies can choose different inspection services based on their needs, adjusting the scale and frequency of inspections flexibly.

Low Initial Investment: There is no need to purchase expensive equipment; companies only need to pay for the inspection services, resulting in lower initial investment.

Strong Professionalism: Outsourced inspection service companies typically have extensive inspection experience and professional technical teams, ensuring reliable inspection results.

Cons:

Higher Long-term Costs: As inspection needs increase, the cumulative cost of outsourced services can be high.

Data Security Risks: Outsourcing inspection to a third party may pose risks of data breaches.

Slower Feedback: Compared to automated equipment, the feedback speed of outsourced services is slower, potentially impacting timely production adjustments.

| Aspect | Visual Inspection Equipment | Outsourced Inspection Services |

|---|---|---|

| Initial Investment | High | Low |

| Long-term Cost | Low | High |

| Inspection Precision | High | High |

| Level of Automation | High | Low |

| Feedback Speed | Fast | Slow |

| Flexibility | Low | High |

| Data Security | High | Low |

| Professional Technical Requirement | High | Low |

Large-scale Production: For companies with large-scale production and frequent rearview mirror glass quality inspections, visual inspection equipment can improve production efficiency and inspection precision, reducing long-term costs.

High Quality Control Requirements: For products with extremely high-quality requirements, visual inspection equipment provides more precise detection, ensuring product quality.

Pursuit of Automation and Real-time Feedback: Companies aiming for production line automation, reducing human intervention, and requiring real-time inspection data to quickly adjust production processes.

Small to Medium-sized Enterprises: For smaller companies with limited production batches, outsourced inspection services with low initial investment are more suitable.

Short-term Projects: For temporary or short-term projects, outsourced services offer flexible inspection solutions without long-term investment.

Lack of Professional Technical Team: Companies without sufficient professional technical personnel to operate and maintain inspection equipment can benefit from the expertise and technology of external professional teams.

In summary, companies should consider their production scale, quality control requirements, financial situation, and technical team capabilities to comprehensively evaluate the pros and cons of visual inspection equipment and outsourced inspection services. This analysis and comparison aim to provide valuable references for companies in making the best choice for rearview mirror glass inspection solutions.

Optical Inspection Machine for Dividing Plates

This dial plate vision inspection machine is speci......

Optical Inspection Machine for Dividing Plates

This dial plate vision inspection machine is speci......

Copyright © Shenzhen City Huya Technology Co., Ltd. All Rights Reserved Sitemap | Powered by XiaoLiang