News

News

Meta Description: Explore the ins and outs of CCD inspection machines, their applications, benefits, and how they revolutionize quality control processes in various industries.

Introduction to CCD Inspection Machines

In the realm of quality assurance, CCD (Charge-Coupled Device) inspection machines have emerged as a pivotal tool. These sophisticated devices leverage advanced imaging technology to meticulously inspect products, ensuring the highest standards of quality. Let's delve into what CCD inspection machines are, how they function, and their significance in modern manufacturing.

A CCD inspection machine is a precision instrument that utilizes a CCD sensor to capture high-resolution images of products. These images are then processed by sophisticated software to detect any defects, anomalies, or inconsistencies. The technology is widely employed in industries such as electronics, pharmaceuticals, automotive, and food processing to enhance product quality and reduce defects.

Image Capture: The machine uses a CCD sensor to capture detailed images of the product. The sensor is highly sensitive to light, allowing it to capture even the smallest details.

Image Processing: The captured images are fed into a computer where specialized software processes the data. The software can identify a wide range of defects, from surface imperfections to structural anomalies.

Analysis and Sorting: Based on the analysis, the machine can sort products into different categories—acceptable, rejectable, or requiring further inspection.

Electronics Manufacturing: In the electronics industry, CCD inspection machines are crucial for detecting defects in components like chips, circuit boards, and LCD screens.

Pharmaceuticals: These machines are used to inspect tablets, capsules, and packaging for any inconsistencies or contamination.

Automotive Industry: CCD inspection machines ensure the quality of automotive parts, such as engine components, sensors, and electronic modules.

Food Processing: The technology helps in inspecting food items for spoilage, foreign objects, and overall quality.

High Accuracy: CCD inspection machines offer unparalleled accuracy in detecting even the smallest defects.

Efficiency: These machines can process a large number of products in a short span of time, significantly reducing manual labor.

Reliability: With minimal human error, CCD inspection machines ensure consistent and reliable quality control.

Cost-Effective: By reducing the number of defects, these machines can save costs associated with product recalls and customer dissatisfaction.

When selecting a CCD inspection machine, several factors should be considered:

Resolution: Higher resolution means better image quality and more precise defect detection.

Speed: The machine should be capable of processing products quickly without compromising on quality.

Software Capabilities: The software should be advanced enough to handle complex inspection tasks and provide accurate results.

Customization: The machine should offer customization options to meet specific industry requirements.

CCD inspection machines have become an indispensable tool in modern manufacturing, providing unparalleled accuracy and efficiency in quality control. Whether it's in electronics, pharmaceuticals, automotive, or food processing, these machines ensure that products meet the highest standards, ultimately leading to customer satisfaction and brand reputation.

By understanding the capabilities and applications of CCD inspection machines, businesses can make informed decisions about incorporating this technology into their quality control processes.

Note: This article is optimized for SEO with appropriate keyword usage and structured content to enhance visibility on search engines.

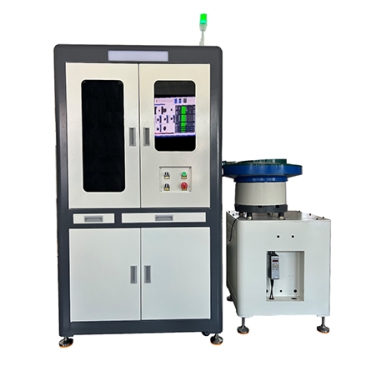

Electronic and electrical visual inspection machine

Electronic and electrical visual inspection machin......

Electronic and electrical visual inspection machine

Electronic and electrical visual inspection machin......

Copyright © Shenzhen City Huya Technology Co., Ltd. All Rights Reserved Sitemap | Powered by XiaoLiang