News

News

Connectors, as devices that transmit current or signals between two active components, are widely used across various industries. From mobile phones, tablets, and computers to refrigerators, air conditioners, and washing machines, and even in automotive, defense, and aerospace fields, connectors are ubiquitous. Every electronic product relies on connectors; without them, they would not function. Therefore, there are extremely stringent requirements for the dimensions and appearance quality of connectors, making inspection work particularly important.

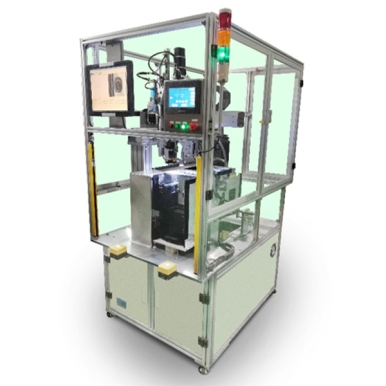

As the functions of connectors continue to increase, their structures become increasingly complex, and their sizes trend towards miniaturization. Consequently, measuring the dimensions and detecting appearance defects of connectors have become more challenging. Traditional manual inspection methods are increasingly unable to meet the quality inspection needs of connector products. At this point, the application of optical sorting machines becomes the inevitable choice to ensure precision, efficiency, and accuracy in inspections.

So, what exactly makes optical sorting machines exceptional?

Firstly, optical sorting machines possess ultra-high inspection precision. Using advanced optical imaging technology, they can accurately capture minute dimensional deviations and appearance defects, ensuring every connector meets strict quality standards. Secondly, the detection speed of optical sorting machines is extremely fast. Compared to traditional manual inspection, optical sorting machines can inspect a large number of products in a short time, significantly enhancing production efficiency.

Additionally, optical sorting machines are simple to operate and highly automated. Using optical sorting machines, you do not need to rely on a large workforce. With minimal training, employees can easily operate the machines, reducing errors and fatigue associated with manual operations. More importantly, optical sorting machines provide comprehensive data analysis and reports, giving you a clear overview of the quality status during the production process. This allows for timely detection and resolution of issues, preventing defective products from entering the market.

In summary, choosing optical sorting machines not only ensures the high quality of connectors but also significantly improves production efficiency, reduces labor costs, and increases the competitiveness of your enterprise. Whether to meet the high standards of your customers or to enhance the production efficiency of your business, optical sorting machines are indispensable tools.

Choose optical sorting machines to elevate your product quality, boost production efficiency, and ensure robust business growth.

Non-standard Customized Visual Inspection Project

Custom-Built Visual Inspection Project for Specifi......

Non-standard Customized Visual Inspection Project

Custom-Built Visual Inspection Project for Specifi......

Copyright © Shenzhen City Huya Technology Co., Ltd. All Rights Reserved Sitemap | Powered by XiaoLiang