News

News

Fully automatic screw locking machines have become an essential part of modern manufacturing, offering efficiency and precision in assembly lines. Selecting the right equipment is crucial for businesses seeking to optimize production and reduce labor costs. This guide provides a detailed overview of how to choose the best fully automatic screw locking machine, focusing on key considerations and answering common questions to help you make an informed decision.

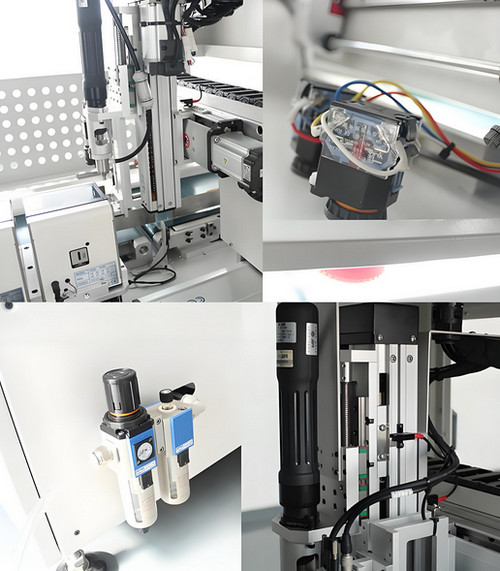

Fully automatic screw locking machines are designed to automate the process of securing screws into components. These machines are commonly used in industries like electronics, automotive, and home appliances, where precise and rapid assembly is critical. The right machine can significantly enhance production speed, consistency, and quality, making it a vital investment for manufacturers.

Before purchasing a screw locking machine, assess your production needs. Consider the volume of products, the size and type of screws used, and the materials being assembled. Machines come in various models, each suited to different production scales. High-volume production lines might require a machine with multi-spindle capabilities, while smaller operations could benefit from a single-spindle model.

Speed and precision are critical factors in the selection process. The machine's ability to consistently and accurately lock screws without damaging the components is essential. Look for machines that offer adjustable speed settings and torque control, allowing customization according to the specific requirements of your products.

Versatility in a screw locking machine can significantly enhance your production flexibility. Machines that can handle various screw sizes, types, and materials are preferable. Additionally, consider whether the machine can be easily reconfigured for different product lines or whether it requires extensive adjustments.

The level of automation is another crucial consideration. Fully automatic machines minimize the need for manual intervention, improving efficiency and reducing the risk of human error. Some models also come with features like automatic screw feeding and alignment, further streamlining the process.

Investing in a durable machine with low maintenance requirements can save time and costs in the long run. Consider the machine's build quality, the materials used in its construction, and the manufacturer's reputation for reliability. Additionally, ensure that the machine comes with a comprehensive maintenance plan and readily available spare parts.

When selecting a screw locking machine for small-scale production, focus on a model that balances cost with essential features like adjustable torque settings and versatility. A single-spindle machine might be sufficient, offering both affordability and efficiency for smaller operations.

Fully automatic screw locking machines offer numerous benefits, including increased production speed, consistent screw torque application, reduced labor costs, and minimized human error. These advantages make them an ideal choice for industries that require high-precision assembly.

The cost of fully automatic screw locking machines can vary significantly based on features, brand, and model. While it's tempting to choose a cheaper option, it's important to weigh the long-term benefits of investing in a higher-quality machine. Consider the total cost of ownership, including maintenance, potential downtime, and the impact on production efficiency.

Choosing the right fully automatic screw locking machine requires careful consideration of your production needs, the machine's features, and long-term cost implications. By understanding these factors and asking the right questions, you can select a machine that enhances your manufacturing process, delivering both quality and efficiency. Investing in the right equipment is not just about meeting current needs but also about future-proofing your production capabilities.

Copyright © Shenzhen City Huya Technology Co., Ltd. All Rights Reserved Sitemap | Powered by XiaoLiang