News

News

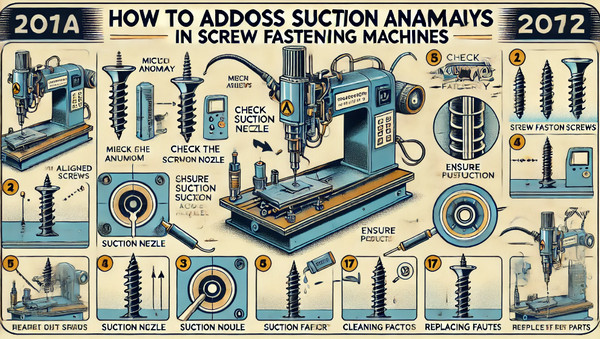

Screw fastening machines are critical in manufacturing for their precision and efficiency in assembly lines. However, suction anomalies can disrupt operations, leading to decreased productivity and potential defects. This article explores the key aspects of diagnosing and resolving suction anomalies in screw fastening machines.

Weak suction can result in screws not being picked up correctly, causing interruptions in the assembly process.

Causes:

Blocked or dirty suction cups

Air leaks in the vacuum system

Insufficient vacuum pressure

Solutions:

Regularly clean or replace suction cups

Inspect and seal any air leaks in the vacuum lines

Ensure the vacuum pump is operating at the correct pressure

Misalignment between the suction nozzle and the screw can lead to failed pickups.

Causes:

Incorrect positioning of the nozzle

Wear and tear of mechanical parts

Calibration issues

Solutions:

Adjust the positioning of the nozzle to align accurately with the screws

Replace worn-out mechanical parts

Calibrate the machine regularly to maintain precise alignment

Worn suction cups can fail to create a proper seal, leading to ineffective screw pickup.

Causes:

Frequent use leading to natural wear and tear

Use of inappropriate materials for the suction cups

Solutions:

Schedule regular inspections and replace suction cups as needed

Use suction cups made from durable materials suitable for the specific screws being handled

Contamination on the suction cups or screws can impede proper adhesion.

Causes:

Accumulation of dust, oil, or other contaminants on suction cups or screws

Inadequate cleaning procedures

Solutions:

Implement a routine cleaning schedule for both suction cups and screws

Ensure the working environment is kept clean to minimize contamination

Regularly inspect the suction cups and nozzles for signs of wear, damage, or contamination.

Check the vacuum pressure at various points in the system to ensure it meets the required specifications.

Use alignment tools to verify the positioning of the nozzle relative to the screws.

Evaluate the materials of the suction cups for compatibility with the screws being used.

Implement a routine maintenance schedule that includes cleaning, part replacement, and system checks.

Ensure operators are trained to recognize the signs of suction anomalies and know the appropriate corrective actions.

Keep an inventory of critical spare parts, such as suction cups and vacuum lines, to reduce downtime during repairs.

Addressing suction anomalies in screw fastening machines requires a systematic approach to diagnose and resolve issues. By understanding the common types of anomalies, their causes, and implementing regular maintenance and inspection procedures, manufacturers can ensure their machines operate smoothly and efficiently. Proper training and maintenance schedules are essential in minimizing disruptions and maintaining high productivity levels.

Copyright © Shenzhen City Huya Technology Co., Ltd. All Rights Reserved Sitemap | Powered by XiaoLiang